Driven by carbon neutrality goals and the growth of the circular economy, the plastic recycling industry is entering a new era of transformation. One major challenge stands out: how to sort complex and diverse plastic waste with high precision, efficiency, and intelligence. GroTech, a leading technology company based in Hefei, China, has risen to this challenge with its specialized plastic color sorter, offering a revolutionary solution for plastic recycling enterprises.

Precise Identification for Multiple Materials — Maximizing Purity

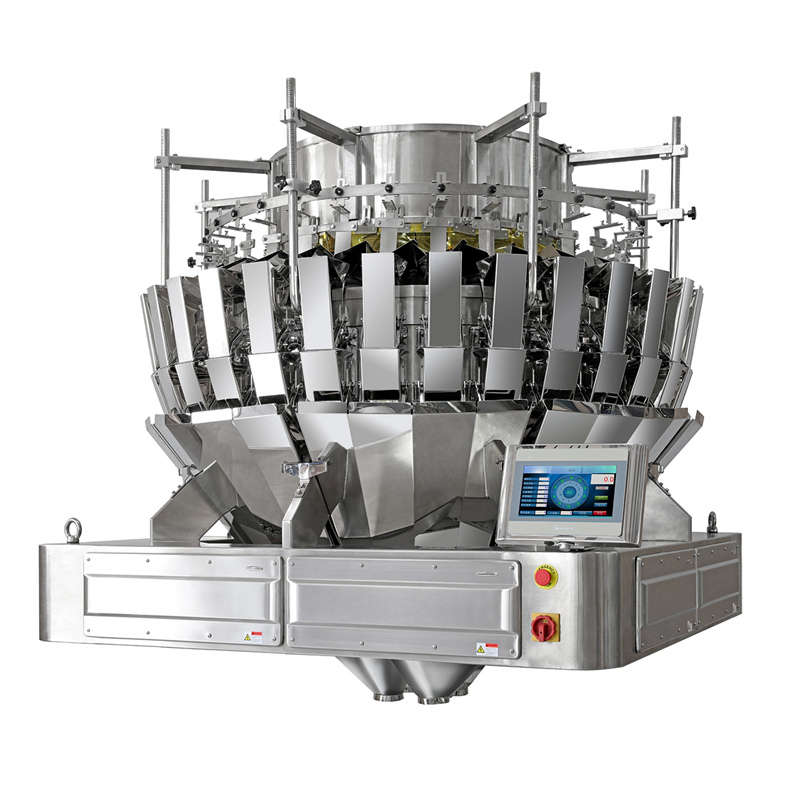

GroTech’s plastic color sorter features a self-developed multi-spectral recognition system that can accurately identify and separate common plastic types such as PVC, PET, PP, PE, and ABS. With the integration of high-resolution imaging and AI-based algorithms, the sorter distinguishes not only by color, but also by material and texture — achieving intelligent sorting of same-color-different-material or same-material-different-color particles.

Whether dealing with industrial plastic scraps or post-consumer recyclables, the machine effectively detects and removes impurities, aged materials, and mixed-color particles — ensuring high purity, low loss, and high throughput.

Modular Design — Seamlessly Adapts to Diverse Production Lines

Designed with flexibility in mind, GroTech's sorter adopts a modular architecture, offering multiple channels, configurations, and capacity options. It supports both dry and wet sorting workflows, making it compatible with a wide range of production lines — with plug-and-play integration and minimal modifications required.

Intelligent System — Easy to Operate, Built for Stability

Equipped with an intuitive smart operating system and graphical interface, GroTech’s sorter allows for one-click start/stop, remote control,. Operators can be trained quickly, significantly reducing labor costs and simplifying maintenance.

The machine is built with industrial-grade components, ensuring long-term stable performance even under 24/7 high-intensity operation — making it ideal for plastic pellet factories, recycling centers, and waste sorting stations.

Proven Results Across China — Trusted by Industry Leaders

GroTech’s plastic sorting solutions have been successfully deployed across numerous provinces in China, including Jiangsu, Zhejiang, Guangdong, Sichuan, and Shandong. Clients have reported dramatic improvements in sorting efficiency and product quality, helping them stay competitive in an increasingly demanding market.

Smarter Sorting for a Greener Future

As a leading innovator in optical recognition and intelligent equipment,GroTech is committed to advancing smart sorting technologies through continuous innovation and dedicated service. Looking ahead, the company will continue to empower the plastic recycling industry with more intelligent, efficient, and eco-friendly solutions — helping to build a sustainable future, one sorted particle at a time.