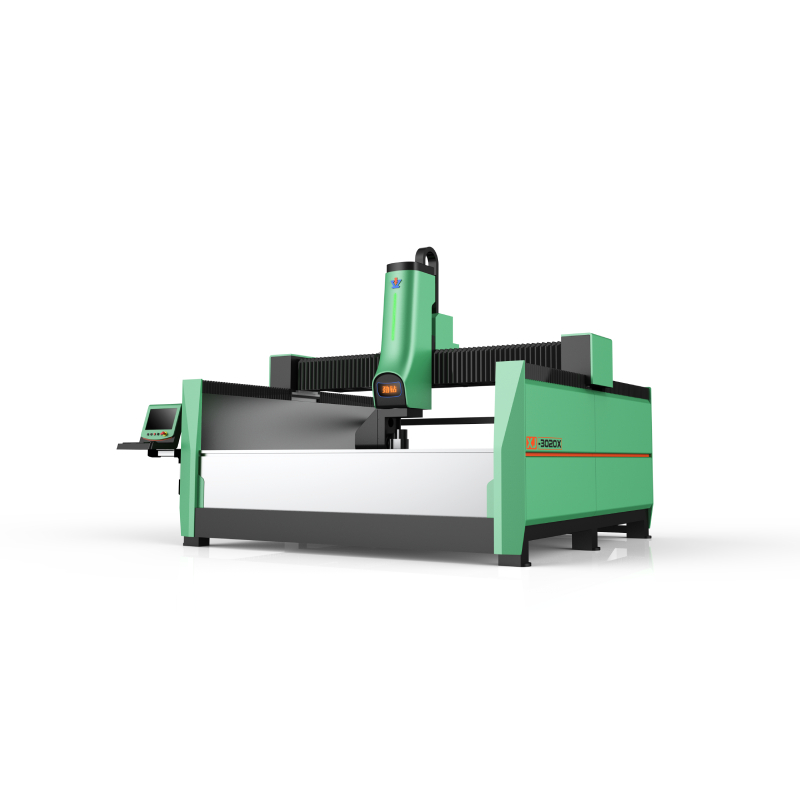

When it comes to stone processing—whether for grand architectural projects or intricate decorative pieces—precision, consistency, and efficiency are non-negotiable. This is where stone profiling machines step in, transforming raw stone blocks into polished, custom-shaped products that define modern design.

1. Core Functional Features of Stone Profiling Machines

Stone profiling machines are engineered to handle the unique hardness and texture of natural and engineered stones (e.g., marble, granite, quartz, limestone). Their key functions are tailored to simplify complex shaping tasks while maintaining accuracy:

1).Custom Shaping & Profiling: The primary function is to create precise, repeatable profiles on stone edges or surfaces. This includes straight edges, bevels, arcs, bullnoses, ogees, and even intricate decorative patterns (e.g., floral motifs or geometric designs). Unlike manual tools, which rely on human skill and often produce inconsistent results, these machines use pre-programmed templates or CAD designs to replicate shapes flawlessly across hundreds of pieces.

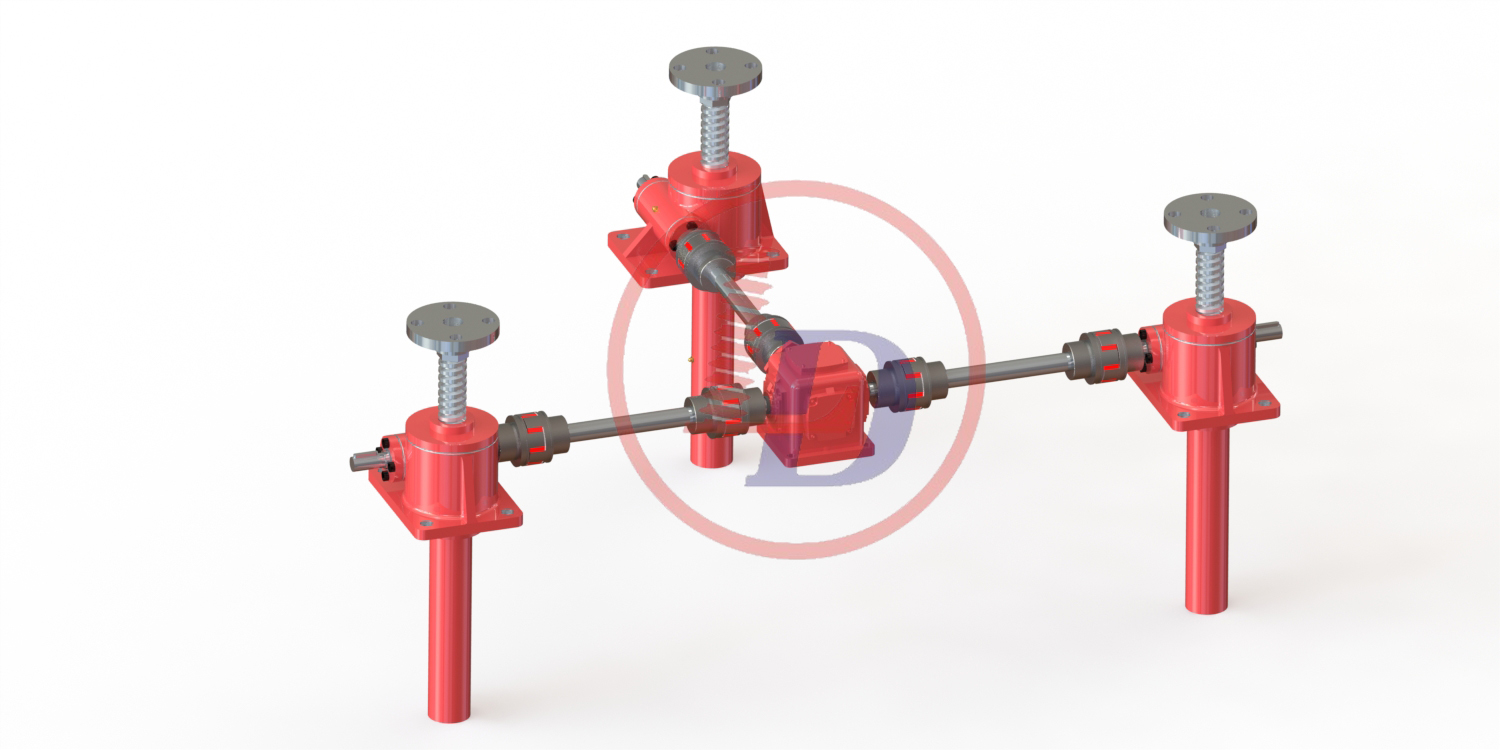

2).Multi-Axis Processing: Advanced models feature 3-axis, 4-axis, or even 5-axis systems, allowing them to work on multiple sides of a stone block simultaneously. This capability is critical for 3D stone products, such as curved countertops, column capitals, or sculptural elements, where precision across all dimensions is essential.

3).Integrated Polishing: Many modern stone profiling machines combine shaping and polishing in one workflow. After cutting or profiling, built-in polishing heads (with varying grits) smooth the stone surface to a high gloss, eliminating the need for separate equipment and reducing production time.

4).Automated Material Handling: To boost efficiency, most machines include automated conveyors, clamps, or robotic arms that load/unload stone slabs. This minimizes manual labor, reduces the risk of injuries, and ensures consistent processing speeds.

5).Real-Time Monitoring & Adjustment: Equipped with sensors and cameras, these machines track cutting depth, pressure, and surface quality in real time. If deviations are detected (e.g., a stone slab with uneven thickness), the system automatically adjusts parameters to maintain precision—avoiding wasted materials and rework.

2. Technical Advantages That Outperform Traditional Methods

Traditional stone processing relies on hand tools (e.g., chisels, grinders) or basic machines, which are slow, labor-intensive, and prone to errors. Stone profiling machines address these limitations with cutting-edge technology, offering unmatched benefits:

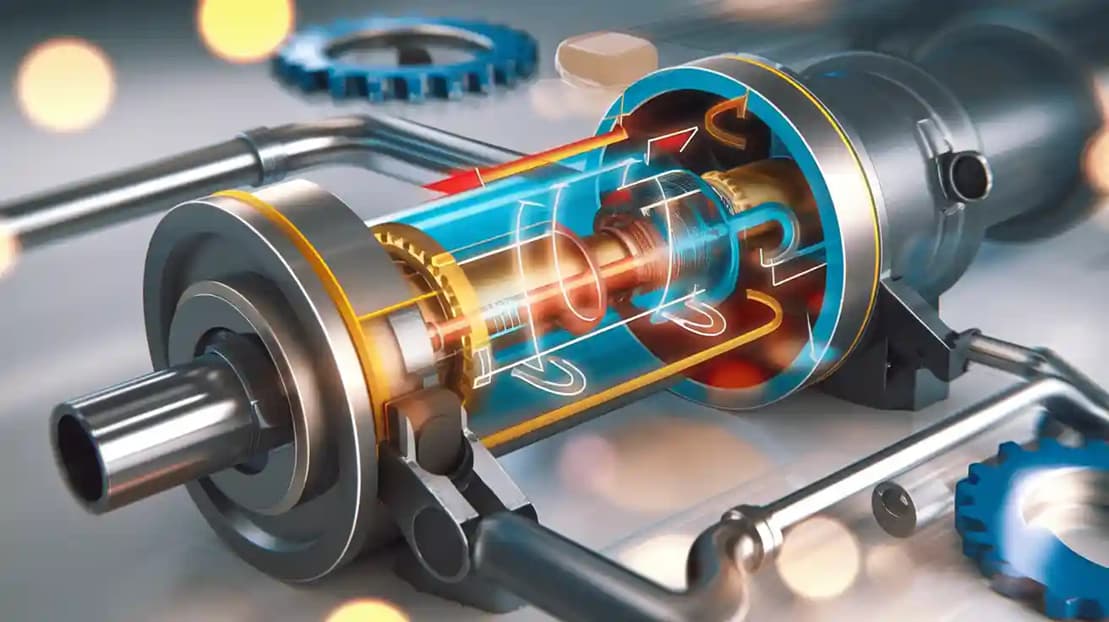

1).Superior Precision: Using CNC (Computer Numerical Control) technology, these machines achieve tolerances as tight as ±0.1mm. This is critical for projects like kitchen countertops (where edges must align perfectly) or historical building restorations (where stone pieces must match original designs).

2).Unmatched Efficiency: A single stone profiling machine can process 5–10 times more stone than a team of manual workers. For example, profiling the edges of 10 marble countertops might take 8 hours manually, but a CNC profiling machine can complete the task in 1–2 hours—freeing up labor for other high-value tasks.

3).Reduced Material Waste: Manual cutting often results in 15–20% material waste due to human error. With pre-programmed designs and real-time adjustments, stone profiling machines cut waste to 5% or less. This is a significant cost-saver, especially for expensive stones like rare granite or marble.

4).Versatility Across Stone Types: Whether working with soft limestone or ultra-hard granite, these machines adapt to different material properties. They adjust cutting speed, blade pressure, and polishing grits based on the stone’s hardness, ensuring optimal results without damaging the material.

5).Consistency at Scale: For large projects (e.g., hotel lobbies, shopping malls, or residential complexes), consistency is key. Stone profiling machines replicate the same profile across every stone piece—no matter how many are produced. This eliminates the “handmade” variation that can ruin the aesthetic of a cohesive design.

6).Ease of Use & Programming: Modern machines come with user-friendly interfaces that allow operators to upload CAD designs, adjust parameters, or save templates with just a few clicks. Even operators with minimal technical experience can learn to use them quickly, reducing training time and human error.

3. Key Application Scenarios in the Stone Industry

1).Architectural Curved Decoration: Processes arc plates for building exteriors/interiors, such as curved wall claddings, circular column casings, and arc cornices, enhancing architectural aesthetics.

2).Countertop & Vanity Edge Arc Processing: Creates curved edges (e.g., bullnose, half-round arcs) on stone countertops (marble, granite) and vanity tops, ensuring safe use and sleek appearance.

3).Landscape Curved Elements: Fabricates arc-shaped stone components like curved garden benches, circular fountain rims, and arc paved borders, fitting natural landscape layouts.

4).Tombstone Curved Details: Adds arc plates to tombstones/memorials, such as curved top edges or arc decorative panels, enriching the memorial’s design.

5).Curved Stone Artworks: Produces arc-structured stone crafts (e.g., curved figurine bases, circular decorative plates) for artistic displays, leveraging precise arc processing.

Final Thoughts: Why Stone Profiling Machines Are a Must-Have

In an industry where precision, efficiency, and cost-saving matter, stone profiling machines are no longer a luxury—they’re a necessity. They eliminate the limitations of manual processing, reduce waste, and open up new possibilities for design (e.g., complex 3D shapes that were once impossible to achieve). Whether you’re a large-scale stone manufacturer or a small artisan, investing in a stone profiling machine can help you stay competitive, meet client demands faster, and deliver high-quality products that stand out.

As technology continues to advance, we can expect even more innovations in stone profiling—from AI-powered design tools to faster processing speeds. For now, though, these machines are already transforming the stone industry—one precise cut at a time.